Industrial RO Spare Parts in Delhi

Industrial Spare Parts Manufacturer: Durable OEM Components for Heavy Machinery

An Industrial Spare Parts Manufacturer produces high-quality components used in machinery across industries, ensuring efficiency, durability, and seamless operations. These manufacturers provide OEM spare parts, heavy machinery replacements, and industrial machine components tailored to meet specific operational needs, helping businesses reduce downtime and maintain peak performance.

In the modern industrial landscape, machinery downtime can cost companies thousands of dollars daily. That’s why working with a reliable industrial spare parts manufacturer is critical. From manufacturing plants to construction and automotive industries, high-quality spare parts ensure that machines operate efficiently, last longer, and perform at their peak.

Choosing the right manufacturer not only guarantees the durability of components but also provides peace of mind that your operations won’t be disrupted due to substandard parts. With industries evolving rapidly, precision, quality, and timely delivery have become the key pillars that define a trusted OEM spare parts supplier.

Who is an Industrial Spare Parts Manufacturer?

An Industrial spare parts manufacturer is a company that designs, produces, and supplies replacement parts for machinery and equipment. Unlike distributors or retailers who only sell parts, manufacturers ensure that every component meets quality standards, industry compliance, and operational requirements.

Key roles of an industrial spare parts manufacturer include:

-

Designing parts that fit specific machines and equipment

-

Ensuring components meet OEM standards

-

Providing custom solutions for specialized machinery

-

Delivering bulk orders efficiently to support industrial operations

By working directly with a manufacturer, industries benefit from quality assurance, cost efficiency, and a streamlined supply chain.

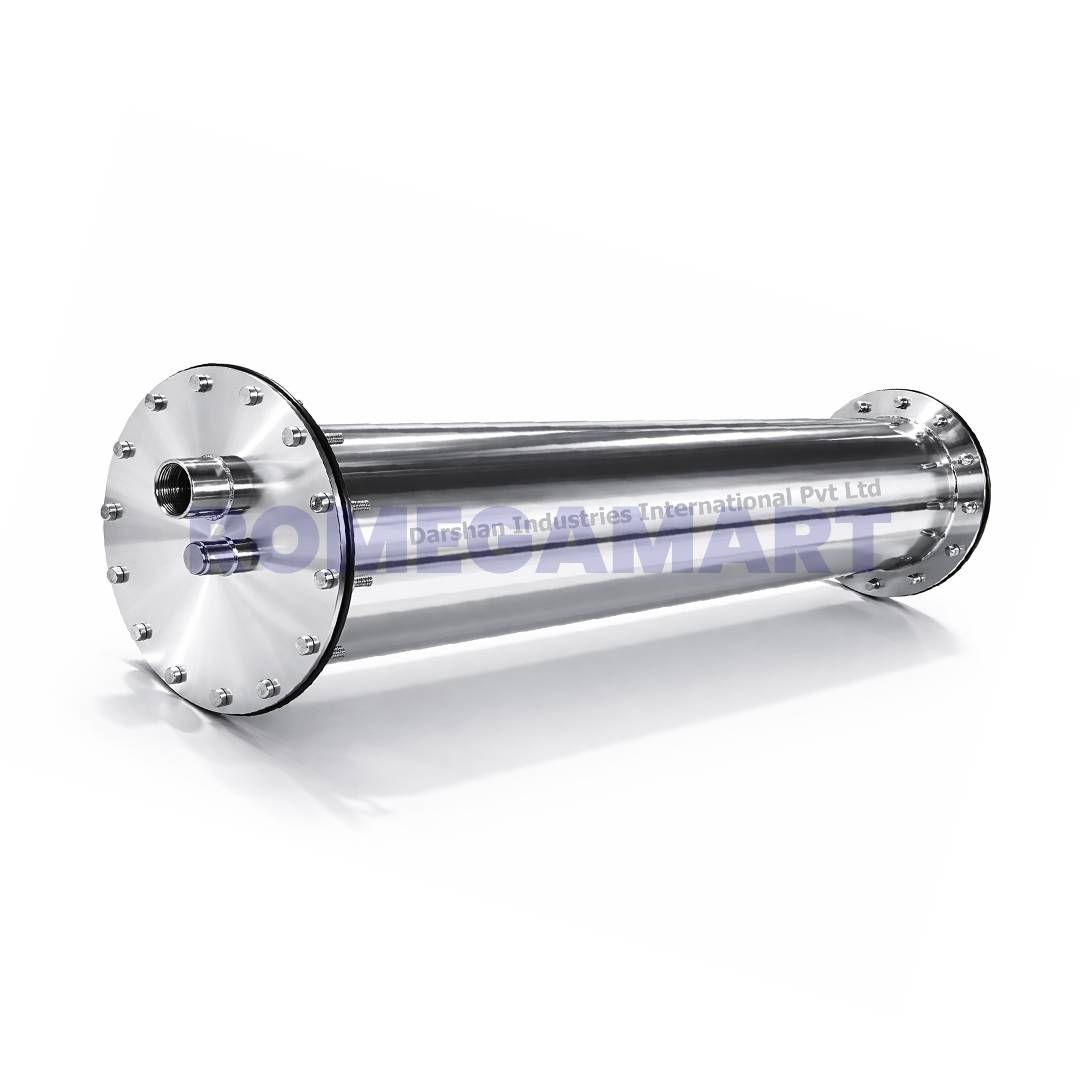

Types of Industrial Spare Parts

Industrial machinery consists of numerous components, each requiring maintenance or replacement over time. Manufacturers produce a wide variety of spare parts, categorized broadly as follows:

Mechanical Components

Mechanical components include parts like gears, shafts, bearings, couplings, and conveyor belts. These are essential for the movement, transmission, and operational efficiency of machinery. High-quality mechanical parts reduce wear and tear, prevent breakdowns, and extend the life of industrial equipment.

Electrical Components

Electrical components such as motors, switches, sensors, and control panels are critical for machine automation and operational accuracy. A reputable manufacturer ensures these parts meet safety standards, voltage requirements, and compatibility with various industrial systems.

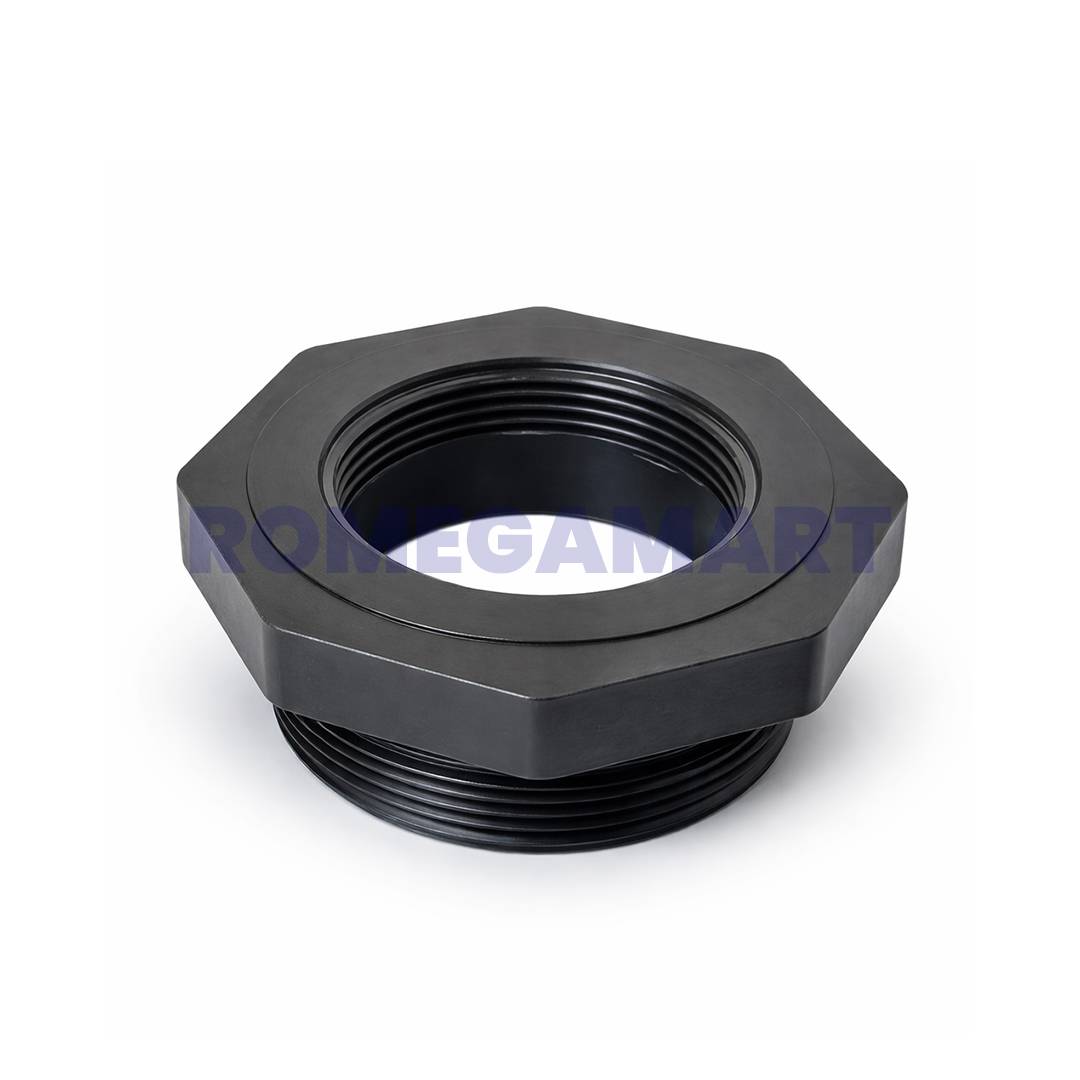

Hydraulic and Pneumatic Parts

Hydraulic cylinders, Pumps, valves, and pneumatic actuators fall under this category. They are vital for industries that rely on heavy machinery and automated systems. Precision engineering and testing are crucial to maintain pressure efficiency and prevent leaks or system failures.

Key Qualities of a Reliable Industrial Spare Parts Manufacturer

Choosing the right manufacturer is as important as choosing the parts themselves. Here’s what sets a reliable OEM spare parts supplier apart:

Product Quality and Compliance

A trustworthy manufacturer adheres to international standards such as ISO and ensures that every component is tested for durability, material strength, and precision. Using certified parts reduces operational risks and increases machine longevity.

Timely Delivery and Supply Chain Efficiency

Industrial operations cannot afford delays. Manufacturers with efficient logistics ensure bulk orders are delivered on time, avoiding downtime. They also provide real-time inventory updates and bulk order handling to support large-scale industrial operations.

Customization and OEM Capabilities

Every industrial setup has unique requirements. The ability to provide custom-designed parts or replicate OEM specifications ensures seamless integration with existing machinery and equipment.

Applications of Industrial Spare Parts

Industrial spare parts are used across various sectors:

Heavy Machinery

Construction, mining, and agricultural industries depend heavily on heavy machinery replacement parts to maintain continuous operations. Reliable parts prevent machine failure, reduce maintenance costs, and enhance productivity.

Manufacturing Plants

Assembly lines, production units, and automated systems require a consistent supply of mechanical and electrical components. High-quality parts reduce defects, improve output, and ensure safety compliance.

Automotive and Transportation Industries

Vehicle assembly plants, logistics, and fleet maintenance rely on precise components to ensure smooth operations. Using OEM-grade spare parts guarantees reliability and safety.

Choosing the Right Industrial Spare Parts Supplier

Selecting the correct supplier is critical for maintaining operational efficiency. Consider the following factors:

-

Reputation and Experience: Years of experience and a proven track record indicate reliability.

-

Range of Products: A wide portfolio ensures you can source multiple components from a single supplier.

-

Technical Support: Manufacturers that provide installation guidance, troubleshooting, and post-sales support add value.

-

Cost vs Quality: Always balance affordability with durability. Cutting costs on low-quality parts can lead to higher downtime costs.

Technological Advancements in Spare Parts Manufacturing

Modern industrial spare parts manufacturers leverage advanced technologies to enhance part quality:

-

CNC Machining: Produces precise components with minimal tolerances.

-

3D Printing: Enables rapid prototyping and custom part production.

-

Automation and Robotics: Ensure consistency in production, reduce human error, and speed up manufacturing.

-

Material Innovation: High-strength alloys, corrosion-resistant coatings, and advanced composites improve durability.

These innovations not only ensure parts are durable but also improve operational efficiency and reduce maintenance costs.

Cost Considerations & Value of Quality Parts

While initial costs may be higher for premium components, investing in quality industrial machine components provides long-term savings:

-

Reduces frequency of replacements

-

Minimizes machine downtime

-

Enhances safety compliance

-

Improves overall operational efficiency

Choosing substandard parts may seem economical initially but often leads to higher maintenance costs and unplanned downtime, affecting productivity and profitability.

FAQs About Industrial Spare Parts

Q1: How do I identify OEM parts?

Look for manufacturer branding, part numbers, certification marks, and compliance with industry standards. Always source from trusted suppliers.

Q2: How often should industrial spare parts be replaced?

Replacement depends on usage, operating conditions, and manufacturer recommendations. Regular inspections help determine the optimal replacement schedule.

Q3: How can I maintain spare parts for longevity?

Routine lubrication, proper storage, and timely cleaning prevent wear and tear. Partnering with a reliable manufacturer ensures access to quality replacements when needed.

Conclusion

A dependable industrial spare parts manufacturer is more than just a supplier—they are a partner in ensuring operational excellence. From providing durable heavy machinery replacement parts to precise industrial machine components, working with an experienced OEM supplier minimizes downtime, improves efficiency, and supports sustainable growth.

Take Action: Partner with a trusted industrial spare parts manufacturer today to ensure seamless operations, reduce maintenance costs, and access high-quality OEM components designed for your industry. Request a quote or download the complete product catalog to explore the full range of solutions.